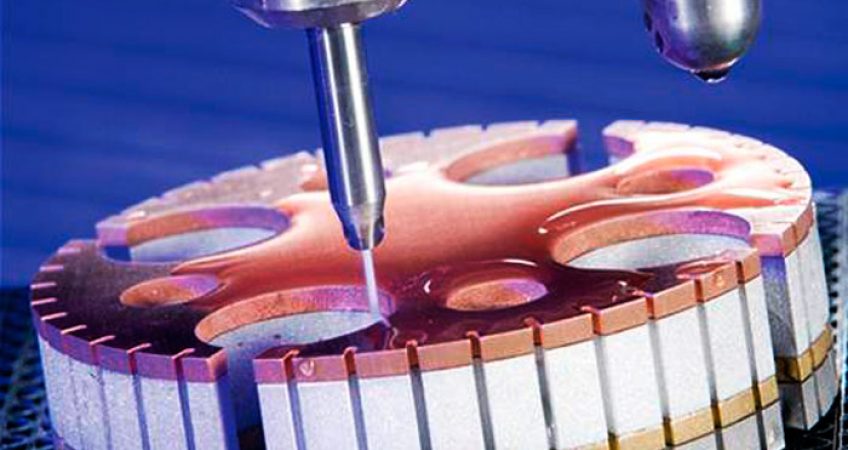

Although it seems like a very simple cut, since it is a water jet technique, it is more complex than it seems. In its most basic form, a powerful jet is controlled at very high pressures. Potential energy is thus converted into kinetic energy. Thus we get a jet of energy for micromachining.

The machinery we use for this process can operate either with pure water jet, or with water and an abrasive. In the case of using pure water, we cut much softer materials than with the abrasive mixture, this is more recommended for harder materials.

Since it is a cold cutting process, it is much more cautious with metals. In addition, it maintains the structure of the metal worked.

If you are interested in the water jet process or have any questions about machining, in Mecanizados Sinc we will advise you every step of the way. We want to offer you the best solutions and always tailored for you. Contact us by calling: +0034 96 652 22 48, or by sending us an email to: mecasinc@mecanizadossinc.com. We will gladly assist you, giving you all the necessary and tailored solutions, in any type of machining, processing and/or finishing of parts.